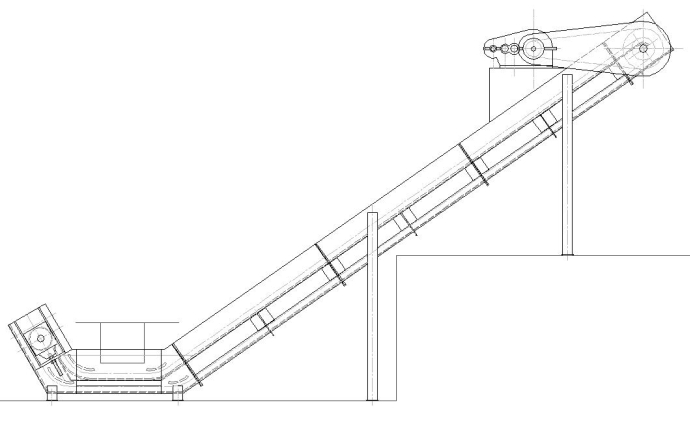

Deslagging systems

Deslagging i.e. collection, cooling and crushing of slag, and then its transport to a storage are performed with the use of high quality devices produced by ELEWATOR S.A.

The basic device used in deslagging process is wet chain dirt trap.

Chain dirt trap consists of:

- sump,

- power unit with a drive,

- tension head,

- chain tie.

Technical features of deslaggers:

- performance Qmax = 60 t/h

- length: Lmax = 40000mm

- width: Bmax = 2500mm

Technical solutions used in deslagger:

- chain tie with welded chains,

- comb with shaped handle ensuring quick assembly and disassembly,

- chains and idler wheels possible to dismount and mount easily,

- metal sheets and sliding guides made of wear resistant steel or basalt,

- gear motor or hydraulic drive,

- chain tightening with a screw-spring mechanism or hydraulic method with complete drive unit,

- overload protection on the mechanical and electrical side,

– anticorrosive coating as required by operational environment,

The sump dimension in chain dirt trap is chosen depending on customer’s requirements. The width of sump depends on required performance. The sump is made as a leakproof construction. The floor of sump is lined with wear resistant metal (DENSIT) or material based on basalt aggregate.

The drive unit of deslagger is placed in a slug dump. The drive unit includes a shaft, transport wheels, bearings, chain wheels, a chain and a power train (gear with driver).

The tension unit with screw-spring or hydraulic tensioner is placed on the opposite site of deslagger drive unit and its aim is to maintain constant tension of chain tie.

Dirt trap’s chain tie consists of high-resistance mining chain, comb and connection of comb and chain.

Deslagging system often requires the use of other devices, such as:

- drag conveyor / drag feeder

- chain conveyor / chain feeder

- push chain conveyor / push chain feeder

- pull conveyor / pull feeder

- bucket conveyor / bucket feeder / elevator

- reversible conveyor / reversible feeder

- weighing conveyor / weighing feeder

- scraper conveyor,

- conveyor,

- feeding hopper channel

- hopper

- charge

- dumping

- vibratory grate

- scraper loader